September/October 2021 Inspectioneering Journal

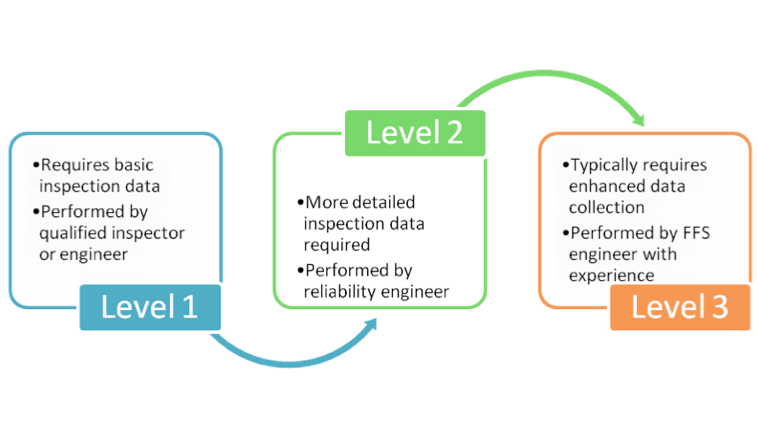

This follow-up article discusses the important topic of establishing Heat Exposure Zones and Level 1, 2, and 3 fitness-for-service assessments following a plant fire.

July/August 2021 Inspectioneering Journal

Part 1 presents a brief overview of the process of assessing equipment in a post-fire "return-to-service" effort and discusses some common issues that may arise during that process.

May/June 2021 Inspectioneering Journal

In this article, FFS assessment methods are summarized and practical guidance is offered for qualifying CUI damage on carbon and low-alloy steels.

March/April 2021 Inspectioneering Journal

Globally accepted FFS procedures for non-metallic components, such as reinforced thermoplastic pipes, do not exist. There may be opportunity in adapting existing procedures for metallic components and their damage mechanisms to composite components.

March/April 2021 Inspectioneering Journal

FFS assessments usually originate from inspection results and often end with a recommended inspection plan. This FFS Forum tries to provide a little better understanding of one particular inspection method: Acoustic Emission Testing.

Partner Content

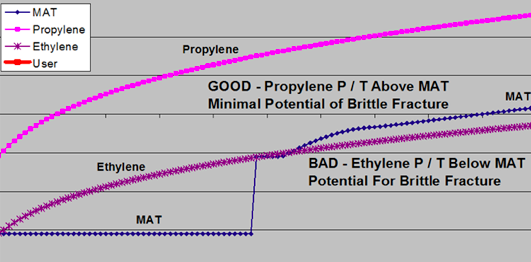

Auto-refrigeration can impose low temperatures onto process vessels and piping causing them to be at risk of brittle fracture, the sudden break-before leak phenomena that can result in catastrophic rupture of the equipment.

January/February 2021 Inspectioneering Journal

The first two parts of this series covered the basics of fracture mechanics and how the FAD is interpreted. This article touches on a few practical points regarding the application of fracture mechanics in a plant environment.

November/December 2020 Inspectioneering Journal

Conventionally, three primary fatigue analysis methods have been used to estimate fatigue life; these are the stress-life (S-N) approach, the strain-life (ε-N) approach, and the fracture mechanics (crack growth) approach.

November/December 2020 Inspectioneering Journal

Every fitness-for-service (FFS) assessment must have a well-defined acceptance criterion. For many damage mechanisms, it's the "remaining strength factor" (RSF). But for crack-like flaw assessment, it's the Failure Assessment Diagram, or FAD.

Blog

A summary of some of the important topics that were discussed at the API Fall 2020 Refining and Equipment Standards Meeting that was held via virtual conferencing.

September/October 2020 Inspectioneering Journal

Fracture mechanics is a branch of engineering that describes the behavior of cracks – how they grow and when they fracture. Fracture of cracks is particularly dangerous because it can happen without warning under normal operating conditions.

Partner Content

FFS assessment techniques are applicable to a wide range of damage types: LTA's, cracks, creep damage, dents, and more. These are very powerful analytical tools that often allow operators to not only keep the plant running, but to keep it running...

July/August 2020 Inspectioneering Journal

Assessment procedures in API 579 are organized by damage mechanism. But what happens when different damage mechanisms are in play since the evaluation criteria may not be compatible?

May/June 2020 Inspectioneering Journal

This article provides an overview of brittle fracture, details on several industry failures, and a summary of deficiencies and concerns with current published methods for screening susceptibility of equipment to potential brittle fracture failures.

May/June 2020 Inspectioneering Journal

There are many places where brittle fracture risk can sneak into your plant and many reasons why a new or revised brittle fracture assessment may be required when reviewing your pressure systems. Don't overlook this dangerous failure mechanism.

Blog

A summary of some of the important topics that were discussed at the API Spring Refining and Equipment Standards Meeting that was held via virtual conferencing.

March/April 2020 Inspectioneering Journal

FMR is a useful tool in many situations. It allows nondestructive evaluation of the surface microstructure that is entirely adequate in many cases. However, it is not a panacea, and there are many conditions where it is inadequate.

Partner Content

In today's chemical and refining industries, sustained long term reliability of facilities is critical to profitability and competitiveness. In fact, history shows that differences in operating expenses between best-in-class refineries, and poor...

January/February 2020 Inspectioneering Journal

There are many sources and occurrences of metal fatigue in the chemical and refining industries. They range from low-cycle thermal stresses in an FCCU, to the relentless pressure cycling of a PSA, to the ultra-high cycles of a rotating pump.

Blog

A summary of some of the important topics that were discussed at the API Fall Refining and Equipment Standards Meeting in Atlanta.

November/December 2019 Inspectioneering Journal

A cornerstone of Level 1 and 2 metal loss assessment methods in API 579 is the concept of measuring thickness on a grid and constructing a "critical thickness profile." These concepts are fundamental to Level 1 & 2 assessments in both Parts 4...

September/October 2019 Inspectioneering Journal

MSDs are an important, but often misunderstood, element of FFS analyses. This column will help readers understand what an MSD is and why it is so important to Fitness-For-Service analysis under API 579.

July/August 2019 Inspectioneering Journal

This is the second of a two-part column on "Creep." This second part discusses the approach to creep assessment in plant equipment.

Partner Content

Inspectioneering and API have teamed up to create the Mechanical Integrity Professional Initiative. The goal of this project is to raise the benchmark on industry knowledge and develop the next generation of SMEs. We believe that equipping MI...

Blog

This blog article provides examples on addressing widely scattered pitting through the performance of a fitness-for-service assessment using the three conditions set out in the API 510 Pressure Vessel Inspection Code.

May/June 2019 Inspectioneering Journal

This is the first of a two-part column on "Creep". It presents an engineering overview of the phenomena, answers the question: "What is Creep?", and provides readers with foundational knowledge for evaluating and managing remaining...

March/April 2019 Inspectioneering Journal

Brittle fracture and material toughness issues are important concerns in equipment design and FFS. These issues increase when temporary start-up and shutdown conditions require more detailed assessments than provided for in vessel and piping codes.

January/February 2019 Inspectioneering Journal

The distinction between primary and secondary loads is certainly important in analysis of pressure systems. But this distinction is also important for plant operations and reliability engineers to keep in mind when dealing with day-to-day problems.

January/February 2019 Inspectioneering Journal

An effective RBI system implementation results in, not only safeguarding your assets & people, but can also reduce unnecessary inspection activities that may be required due to conventional & nonsystematic approaches.

Partner Content

How is reliability affecting your bottom line? Download our Economics of Reliability report, where Pinnacle analysts take data from the oil refining industry and dive into how that key sector is being affected by reliability today.

November/December 2018 Inspectioneering Journal

In this edition of the FFS Forum, Greg addresses some issues associated with inspection of vessels that have been in service for a number of decades, and offers some tips for reliability and inspection to follow when inspecting these older vessels.

Blog

A quick summary of some of the important topics that were discussed at the Fall Meeting, including the upcoming API Inspection and Mechanical Integrity Summit, subcommittee activities, and progress with the API Individual Certification Program.

September/October 2018 Inspectioneering Journal

In this column, I touch on what I see as an underused FFS technique for corrosion assessment: point assessment of corrosion – a technique that does NOT require a thickness grid. The reason I find this technique useful is largely because it's...

July/August 2018 Inspectioneering Journal

API 579-1 is a complex document covering several different types of equipment that may contain flaws or damage. Due to its complexity, this article condenses it into six things you need to know.

May/June 2018 Inspectioneering Journal

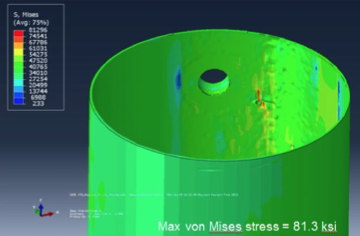

This article details the experience an oil company had when using FEA to evaluate the implications of a damaged pipeline. Specifically, it presents an efficient method that combines analytical techniques with FEA to determine the pipeline's...

Partner Content

Download Pinnacle's Economics of Reliability Report - Refining to see how reliability is affecting profitability.

May/June 2018 Inspectioneering Journal

There is concern in the industry over recent findings of reduced toughness fittings and flanges at risk of brittle fracture. This article provides an overview; possible contributors; measures taken to address; and a proposed FFS approach to address...

January/February 2018 Inspectioneering Journal

Given the concern throughout industry regarding the potential for brittle fracture failures, PWHT guidance to address potential issues arising from the recent changes in PWHT code requirements for carbon steel is examined in this article, and...

November/December 2017 Inspectioneering Journal

In-service equipment failures present a considerable challenge to reliability engineers. This article presents a case study of a convection tube failure in a furnace and the analyses that were performed to understand the root cause and determine the...

November/December 2016 Inspectioneering Journal

This article exhibits how modern inspection methodologies combined with innovative computational analysis practices demonstrate the value of conducting fitness-for-service (FFS) assessments on sectional piping.

July/August 2016 Inspectioneering Journal

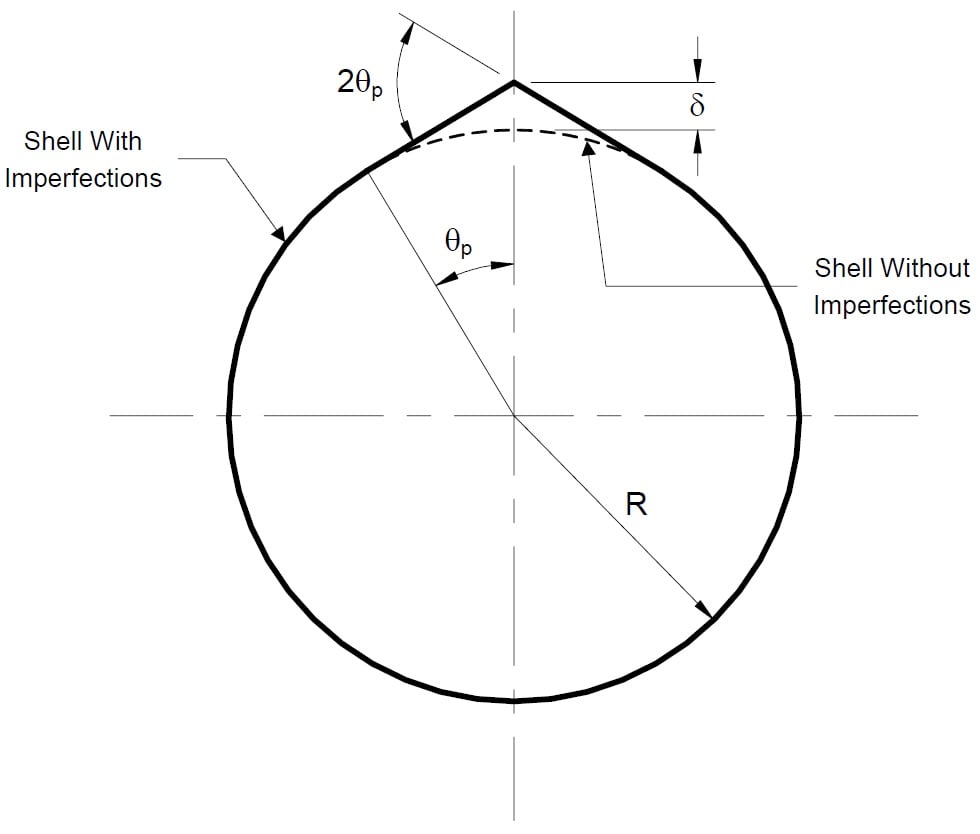

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.

Partner Content

Gecko's TOKA Flex robot is designed to give unprecedented access to piping systems with a robust ultrasonic data-collection capability. The Flex, our most advanced RUG robot, is equipped to find and collect the critical inspection data you need....

July/August 2015 Inspectioneering Journal

Asset managers need to know when repairs and replacement are required for many reasons, including safe operation, accurate budgeting, replacement planning, and on-going reliability. When predicting design life based on a simple, linear corrosion...

Blog

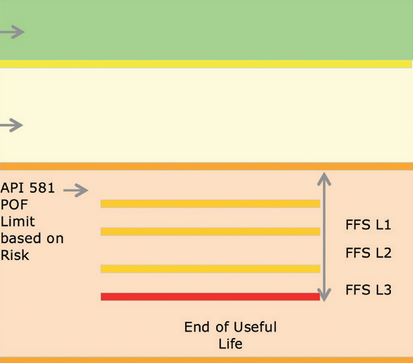

There are numerous benefits to adding fitness-for-service (FFS) assessments to energy sector reliability projects. The acceptance of API 579/ASME FFS-1 is increasing across the energy sector and other industries, as these benefits have been...

September/October 2014 Inspectioneering Journal

Maintaining mechanical integrity for aging power boilers can be challenging. This article provides a case study on how mitigating one damage mechanism led to the discovery of another, and how refinery engineers collaborated with industry experts to...

November/December 2013 Inspectioneering Journal

While there are many types of damage mechanisms that can occur in a piece of equipment, localized metal loss is one of the most common. If an inspection reveals that metal loss has occurred, many questions are raised...

November/December 2013 Inspectioneering Journal

Auto-refrigeration is a process where an unintentional and/or uncontrolled phase change of a hydrocarbon from a liquid state to a vapor occurs, resulting in a very rapid chilling (refrigeration) of the liquid containing local equipment and/or...

September/October 2013 Inspectioneering Journal

Even though oil and gas pipelines and their related facilities are generally safer for people and the environment compared to other means of transportation, occasional leaks and failures due to corrosion and other defects have become an issue in...

September/October 2007 Inspectioneering Journal

The assessment procedures in this Standard can be used for Fitness-For-Service assessments and/or re-rating of equipment designed and constructed to recognized codes and standards, including international and internal corporate standards.

September/October 2007 Inspectioneering Journal

The assessment procedures in this Standard can be used for Fitness-For-Service assessments and/or re-rating of equipment designed and constructed to recognized codes and standards, including international and internal corporate standards.

September/October 2007 Inspectioneering Journal

In May of this year, a workshop was presented at the annual NPRA Reliability and Maintenance Conference at the George R. Brown CC in Houston. This article is a reader’s digest summary of what was presented at that workshop by the four...

July/August 2005 Inspectioneering Journal

This bulletin is part of a series of WRC Bulletins that contain the technical background and other information to evaluate damage mechanisms in various industries to facilitate the use of API 579. These bulletins, shown below, will be updated based...

May/June 2005 Inspectioneering Journal

API is preparing to release the next edition of API 579 Fitness-For-Service (FFS) the first quarter of 2006. The many major enhancements that have been made to the next edition of API 579 will permit Owner-Users to evaluate new types of damage...

November/December 2004 Inspectioneering Journal

Several new API inspection recommended practices exist in which inspectors need to be knowledgeable and qualified. This article details some of those standards.

May/June 2002 Inspectioneering Journal

We have discussed various factors that can affect the reliability of NDE techniques (i.e., probability of detection - POD and sizing accuracy) in Part 1. In general, it is difficult to quantify these uncertainties. In fact, it is impossible to fully...

March/April 2000 Inspectioneering Journal

The release of API RP579 will bring about some changes to other existing API standards. The plan is to offer an integrated suite of API standards, where information is presented once and the other documents refer and are linked to that information.

Source: https://inspectioneering.com/tag/api+579

Posted by: muimuigogertye0272187.blogspot.com

0 Comments